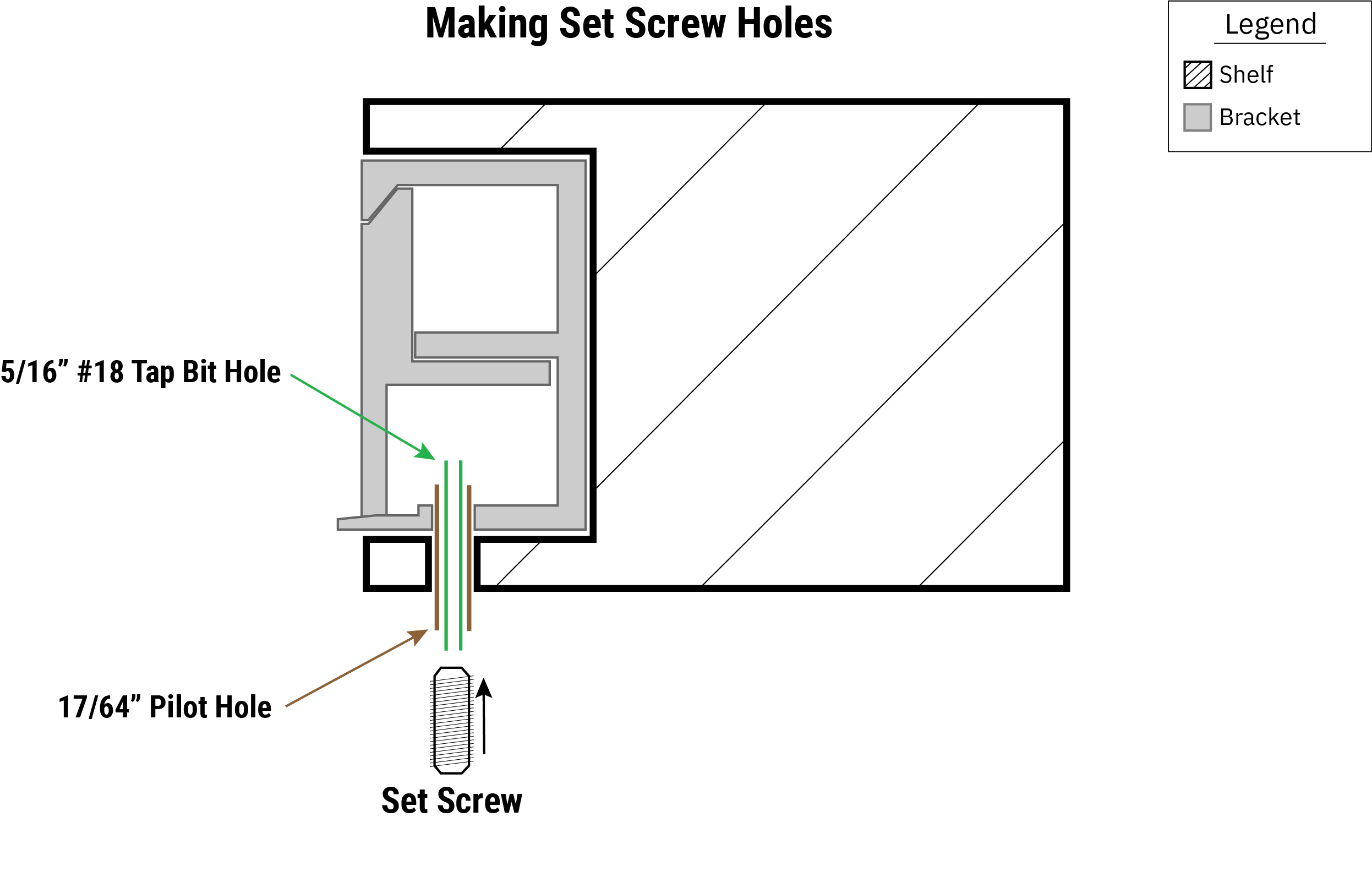

When making the hole and tap in the 1 ½” tall aluminum bracket, we recommend using a 17/64” drill bit to pre-drill the pilot holes for your set screws as needed along the bottom of the female bracket.

Then, switch to the taper tap bit (5/16 – 18 NC) and drill through your pre-drilled pilot holes to make the thread through the wood and bottom section of the female bracket that will then accommodate the #18 - 5/16” set screw.

We suggest going in and out 2 or 3 times. Now the set screw can be screwed in with ease.

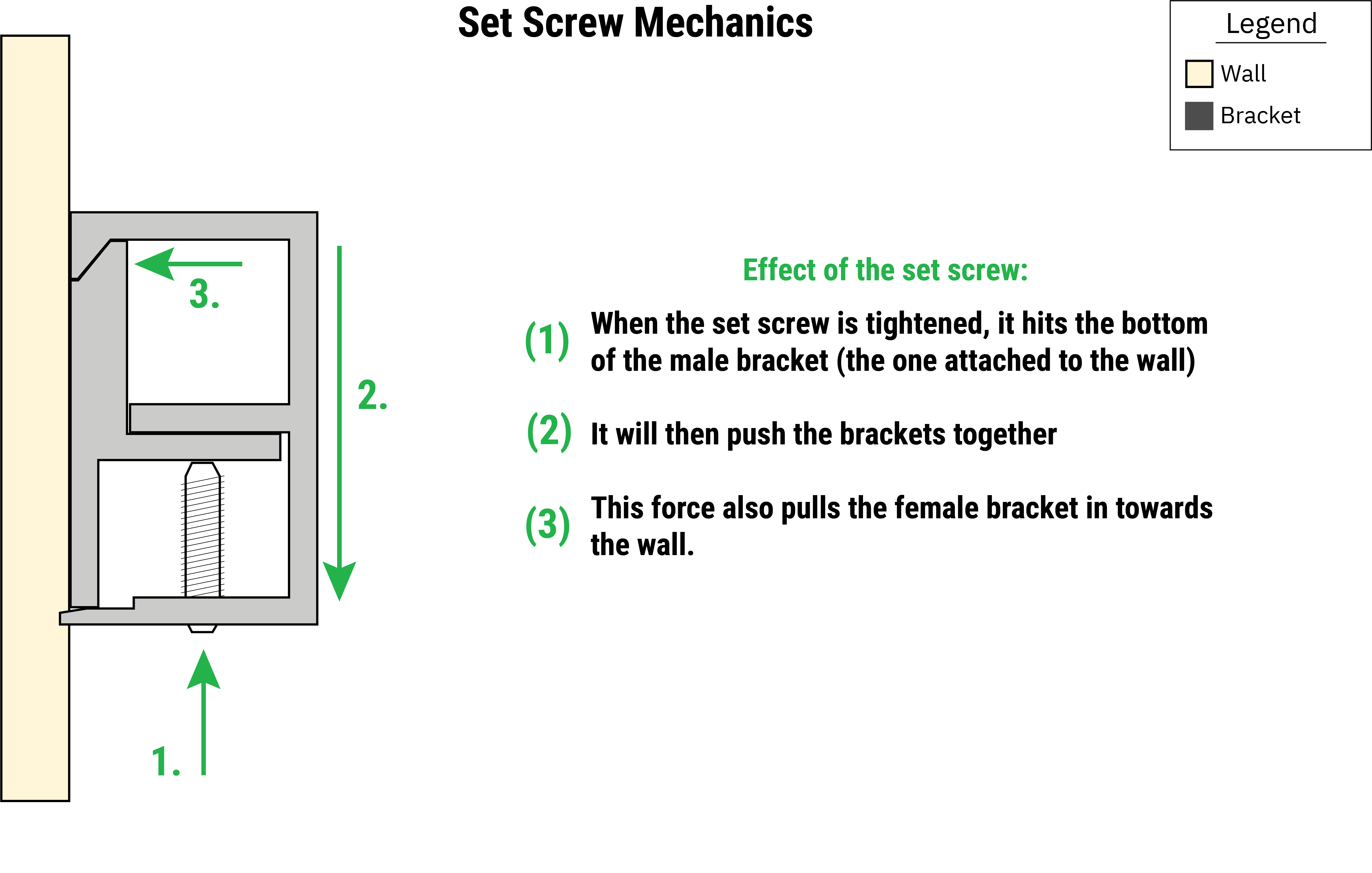

On a 2-inch thick shelf a ¾” long #18 set screw is in order. A 5/8” long set screw can be used but is not recommended. A ½” long set screw is too small. It will screw itself all the way in and fall into the void between the male and the female bracket. If your shelf is thicker, you can use as long a set screw as you can find. The longest we found was 4 inches.

Please remember: The pre-drilled hole should be in the center of the thicker part at the bottom of the female bracket.

The below sketch is an illustration of the set screws purpose and function. When you tighten the screw, it will hit the inner ledge of the male bracket and pull the female bracket down.

*Note that you can also use smaller/thinner set screws (tap size such as 10-24 NC or a 10-32 NF or a ¼ -20 NC) but we generally use and recommend the 5/16 – 18 NC tap bit.